Open-pit mining is a comprehensive project covering many aspects. It not only includes common transportation, mining, ventilation, etc. but also provides enterprise management, blasting, machinery, environmental protection and many other contents. Compared with other industries, it’s own. There are many unsafe factors, and both the work itself and the workplace are dangerous. Therefore, we must pay attention to the implementation effect of safety management measures scientifically and effectively implement various safety operations, to ensure the personal safety of relevant personnel.

Blasting is one of the methods commonly used in open-pit mining, and it is also one of the main factors that are most prone to accidents. Therefore, to prevent mine safety accidents, we must first start with strict regulations on blasting safety systems. First, blasting technicians must receive strict blasting technology training and professional safety education and be able to master scientific and accurate blasting safety regulations and correct, safe operation methods. Secondly, the blasting preparation for blasting operations, the processing of the cartridge, and the blasting inspection must be scientific, accurate and complete. Third, before the blasting is officially carried out, it is necessary to understand the blasting environment and weather conditions. It is strictly forbidden to carry out blasting operations at night, thunderstorms, and dusk. Before blasting, the blast hole must be reconfirmed to prevent problems such as chaotic holes, water accumulation and stuck holes.

Mining and loading work is an essential part of the entire mining industry. It includes not only the acquisition and loading of related materials by excavators and loaders but also the operation of various equipment and the transportation of associated vehicles. The sirens and horns of the excavator must be intact, and corresponding signals must be sent out in advance during various operations such as moving or working; When excavators, loaders, etc. are operating, no one is allowed to stop under the bucket and cantilever and within the range of working surface;

It is forbidden to overfill and unevenly load-related transportation equipment to avoid accidents such as overturning; When loading and unloading goods, the driver of the vehicle shall not stay in the driver’s cab and the range of loading equipment without reason;

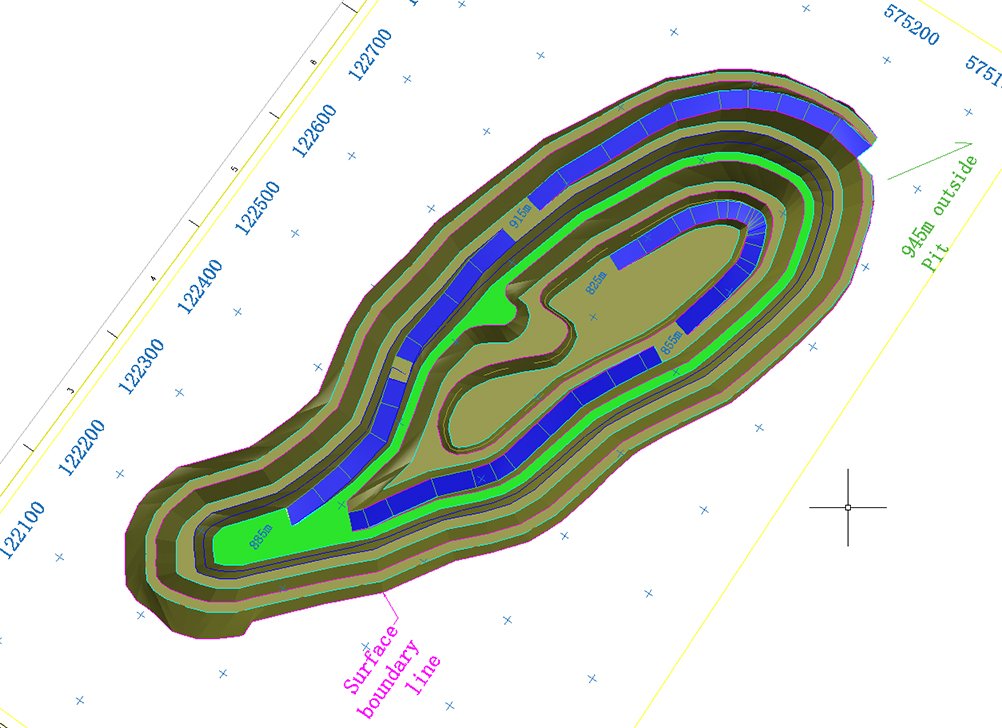

Slope safety management is an essential part of the safety management of open-pit mines, and it has a direct relationship with the safety of open-pit mining. When we conduct daily safety management, we should abide by the following principles. First of all, we must conscientiously implement the policy of “concentration of exploitation and exploitation, and separation first.” Secondly, front-line safety management personnel should conduct a comprehensive inspection of the stope, and promptly report and deal with safety issues such as large pumice and turquoise that are easy to collapse. Once again, we must strengthen the work of side gangs and stopes in the rainy season and pay attention to the stability verification of the slope after blasting and heavy rain. Finally, the slope should be trimmed and cleaned frequently to maintain the continuous stability of the slope. Open-pit mining process Open-pit mining consists of three links: stripping, mining and trenching. The primary production process is perforation, blasting, shovelling of ore (rock), transportation of ore and rock discharge.